Fort Siloso: The Guns of Singapore 7 Inch RML Gun of 6½ Tons

The Gun

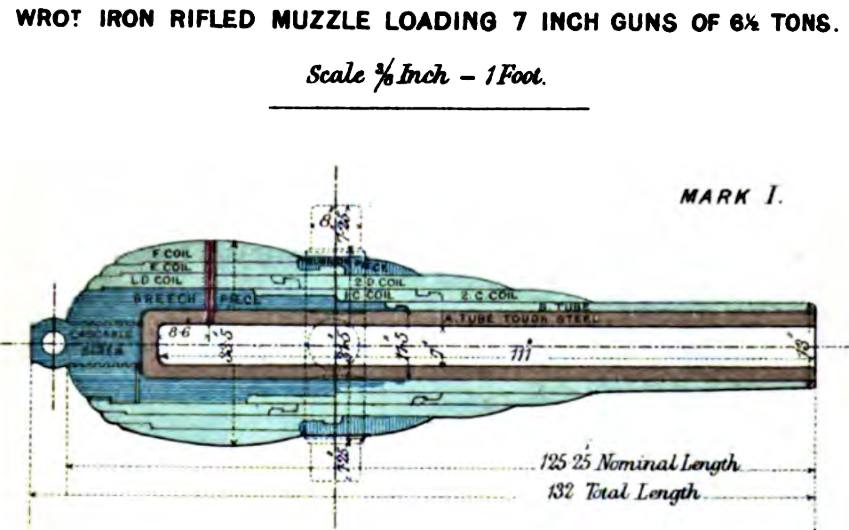

The 7 Inch RML Gun of 6½ tons (6604 kg) (barrel weight) was introduced in to service with the Royal Navy in 1865. Three Marks of the gun were built, with the Mark I seeing land service in Singapore at at three forts; Fort Siloso, Fort Blakang Mati East (later renamed Fort Connaught) and Fort Pasir Panjang.

The gun was designed by the Royal Gun Factory, and was manufactured by the Royal Arsenal at Woolwich. In excess of 330 Guns were manufactured.

Many of the guns were taken in to use by the Royal Garrison Artillery (RGA), which was a branch of the Royal Regiment of Artillery (RA), and which was responsible for manning the guns forts and fortresses. The RGA lost its separate identity and was was absorbed in to the RA in 1924.

The Mark I Gun had quite a distinctive shape and subsequently became known as a ‘Bottle Gun’. The shape of the gun being described in an ordnance manual:-

“Externally the breech is rounded off, giving the gun somewhat the shape of a soda water bottle, and it has several steps in front of the trunnions.”

The gun barrel has a length length of 132 inches (335 cm). It is made up of:

- An A Tube of toughened steel. This is rifled with three grooves.

- The breech piece and B Tube of Wrought Iron

- Trunnion ring and the Cascable of wrought iron

- Six coils of wrought iron.

- The Cascable

The 7 Inch RML Gun was the first gun to incorporate ‘Woolwich’ Rifling (see Glossary), which was a modification of a French system of rifling. These guns were the first of what were to become known as Woolwich Guns, meaning:-

The 7 Inch RML Gun was the first gun to incorporate ‘Woolwich’ Rifling (see Glossary), which was a modification of a French system of rifling. These guns were the first of what were to become known as Woolwich Guns, meaning:-

“Wrought iron M.L. guns built up on Sir W. Armstrong’s principle, improved upon by hooking the coils over one another, and having solid ended steel barrels, rifled ...... for studded projectiles”

The ‘A’ tube was rifled with three grooves with a uniform 1 turn in 35 calibres (1 turn in 245 inches). The bore of the barrel is 111 inches (282cm), with the rifling extending 95·935 inches (243.7cm) from the muzzle.

A Vent was bored into the breech end of the barrel, reaching into the rear of the ‘A’ Tube. This was lined with a bush. The vent was to allow the flash from a Friction Tube to reach the propellant cartridge and ignite its contents. The bush was screwed in, so was replaceable when the effects of firing wore it out.

The Handbook for the gun stated that the gun should be “Examined after every 100 rounds”.

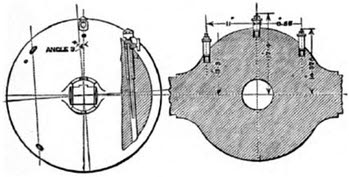

LEFT: Fittings for the Gun Sights. The gun had fittings for a total of six sights; two Tangent (side), one Centre Hind, and three Fore (Trunnion) Sights. The Trunnion Sight used in conjunction with the Centre Hind Sight was termed the ‘Centre Fore Sight’

LEFT: Fittings for the Gun Sights. The gun had fittings for a total of six sights; two Tangent (side), one Centre Hind, and three Fore (Trunnion) Sights. The Trunnion Sight used in conjunction with the Centre Hind Sight was termed the ‘Centre Fore Sight’

RIGHT: The Fore Sight. Called a ‘Drop Sight’, as it was dropped into its socket.

Ammunition

Shells

The main shell used by the gun was Palliser shell of 115 lbs, which was for use against armoured warships. This shell was propelled by what was called a ‘Battering Charge’. The guns were also capable of firing Shrapnel and Common Shell. There was also a ‘Double’ Common Shell which was longer than the standard Common Shell. This contained approximately double the bursting charge. This shell was was unstable in flight, and inaccurate beyond 2,000 yards.

Brass studs were inserted into the sides of the shells. These studs engaged the rifling in the gun barrel to impart a stabilising spin to the shell.

Propellant Charges

The propellant charge for the gun was RLG (Rifle Large Grain) or P Gunpowder. This was made up into silk enclosed Cartridges. Hoops were placed round the cartridges to ensure that the shape was maintained. The diameter was checked by means of metal ring gauges. Length was also checked with a gauge. Measurements are given in Imperial units.

| Type | Length | Diameter | Weight |

|---|---|---|---|

| Battering Charge — P | 22·5 to 23·5 | 6·5 | 30 |

| Battering Charge — RLG | 18·3 to 19·3 | 6·4 | 22 |

| Full Charge — RLG | 13·5 to 14·3 | 6·4 | 14 |

| Reduced Charge — RLG for saluting purposes only |

9·5 to 9·75 | 6·4 | 10 |

The Gun Detachment

A Detachment (Gun Crew) of an Officer and 10 men were required for the 7-Inch Gun.

The Officer Commands the Detachment, and takes post under cover.

No. 1. Commands, directs or superintends the boring of and fixing of fuzes, lays (aims) the gun, and makes ready to fire.

No.2. Swabs out, rams home ammunition, runs up (positions the gun for firing) and elevates the gun.

No.3. Swabs, loads, uncaps the fuze when in the bore, rams home, runs up and elevates.

No.4. Attends to side-arms and supplies them to No.2. Elevates and attends to clamping of elevating gear. Transverses the gun.

No.5. Attends to the Vent, elevates, supplies wedge wads*, attends to clamping of elevating gear, traverses, and fires.

No.6. Provides the No.3 with cartridges.

No.7. Attends to the fuzes, brings the projectile to the gun and places it on the loading derrick.

No.8. Attends to the cartridge store, and gives cartridges to the No.6.

No.9. Assists the No.7.

No.10. Attends to the shell store, issues shells, firing tubes and fuzes.

* Wedge Wads were two wooden wedges each of 5½ inches in length, connected by a 6½ inch length of cane. This was rammed into the barrel after the shell had been loaded.

The Inefficiency of the Gun

Whilst the gun might have been what was needed when it first entered service, it was not considered to be fit for purpose in later years. Many reports made mention of its poor powers of penetration of armour and other shortcomings. Two pieces of correspondence will suffice to demonstrate this.

Letter from C.B.H. Mitchell, the Governor to Maj. Gen. Vaughan Jones Commanding the Troops 2nd January 1895 concerning reports the General had forwarded from the C.R.A. (Commander Royal Artillery).

“...... I would also beg to remind you that the arrangements for running out this gun did not work satisfactorily. It will be within your recollection that an attempt was made to train the gun on a steamer that was approaching the harbour, at a speed of about 9 knots, and that although the range was reported from the range-finder to be 1550 yards at the time the order was given, the steamer had entered the harbour before the gun could be trained upon her, although during the whole of her passage she was well within the arc of fire of the gun in question ..... ”

From Lt D. Paul RA, Inspector of Ordnance Machinery Royal Artillery To Divisional Adjutant Royal Artillery Singapore 2nd December 1895.

Sir,

I have the honour to forward a report on the 7" RML Mountings in this command and the difficulties in traversing them during the mobilization on Saturday, 30th Nov. 1895.

These mountings are traversed by means of an iron-shod lever whose effectiveness as a traversing medium entirely depends on the amount of frictional resistance between it and the racer. In dry weather when is slightly coated with rust the sole of the lever gets a good grip on the racer and does not slip, but, if the racer becomes wet or greasy, the lever slips and will not bite the rail when pressure is applied.

On Saturday a heavy shower of rain had fallen, completely wetting the trucks and racers and the levers would not traverse the mountings for the reasons stated. The pivots and the axles of the trucks have recently been overhauled so the difficulty of traversing the mountings was not in any way due to them.

The difficulty experience in traversing these mountings has often been reported and in forwarding a proposal for a traversing gear on 19.4.93, the C.R.A. remarked as follows:- “At present the traversing is very unsatisfactory. It is necessary that some means be adopted to make the guns efficient for service purposes”.

H.R.H. the C. In C. Did not think it necessary to take any further steps in the matter.